A Swabian success story

2017

2017

Expansion of direct sales RENNER is expanding [...]

2016

2016

RF-HE 400 Filter series RF-HE 400 [...]

2015

2015

RSPM 40 Canned motor pump in the [...]

2015

RT-VC 100 Vertical centrifugal immersion pump RT-VC [...]

2014

2014

RSPM 1.5 Canned motor pump 120 W [...]

2013

2013

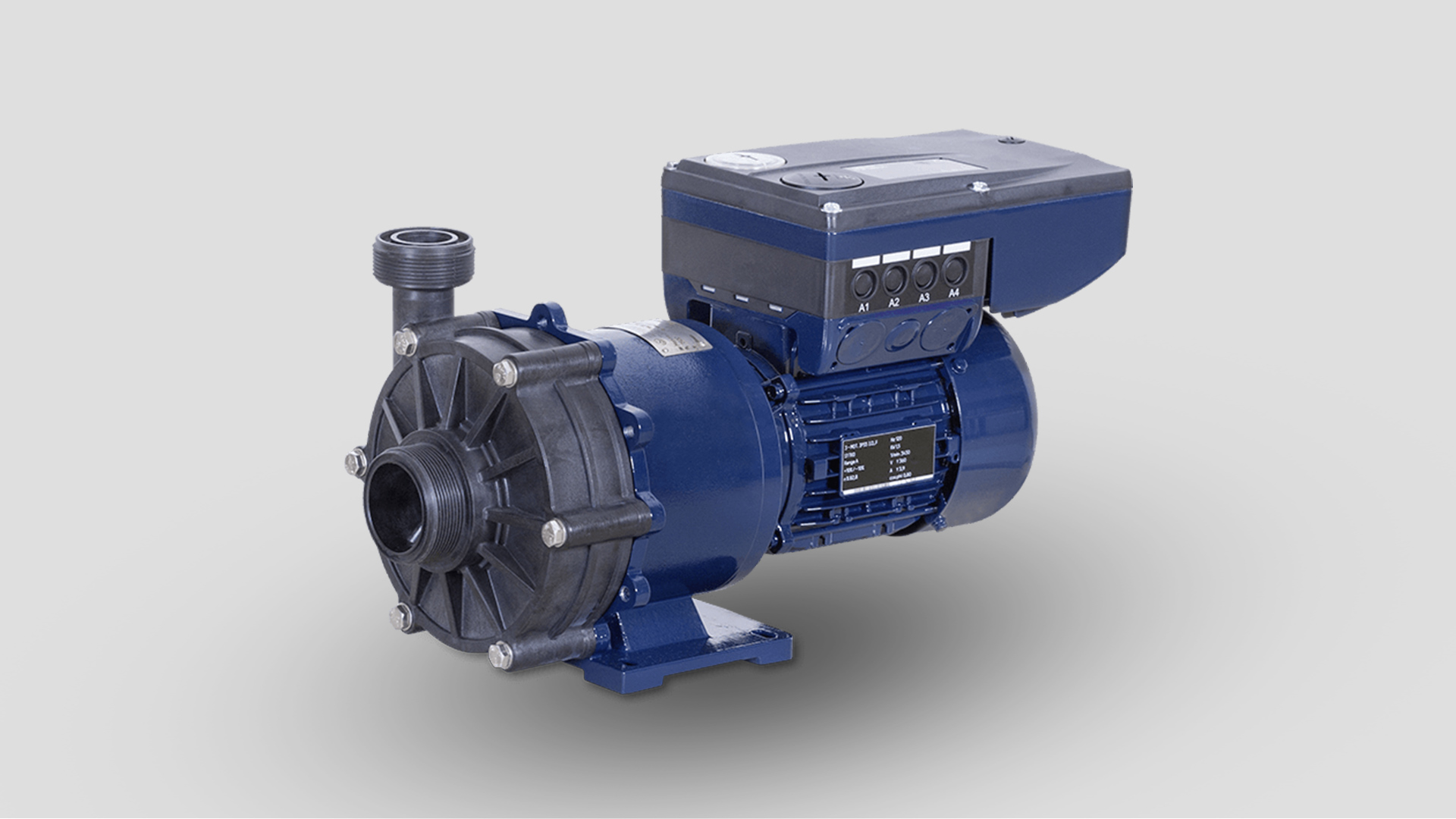

RM-KM – Plastic encased versions of magnetic centrifugal [...]

2012

2012

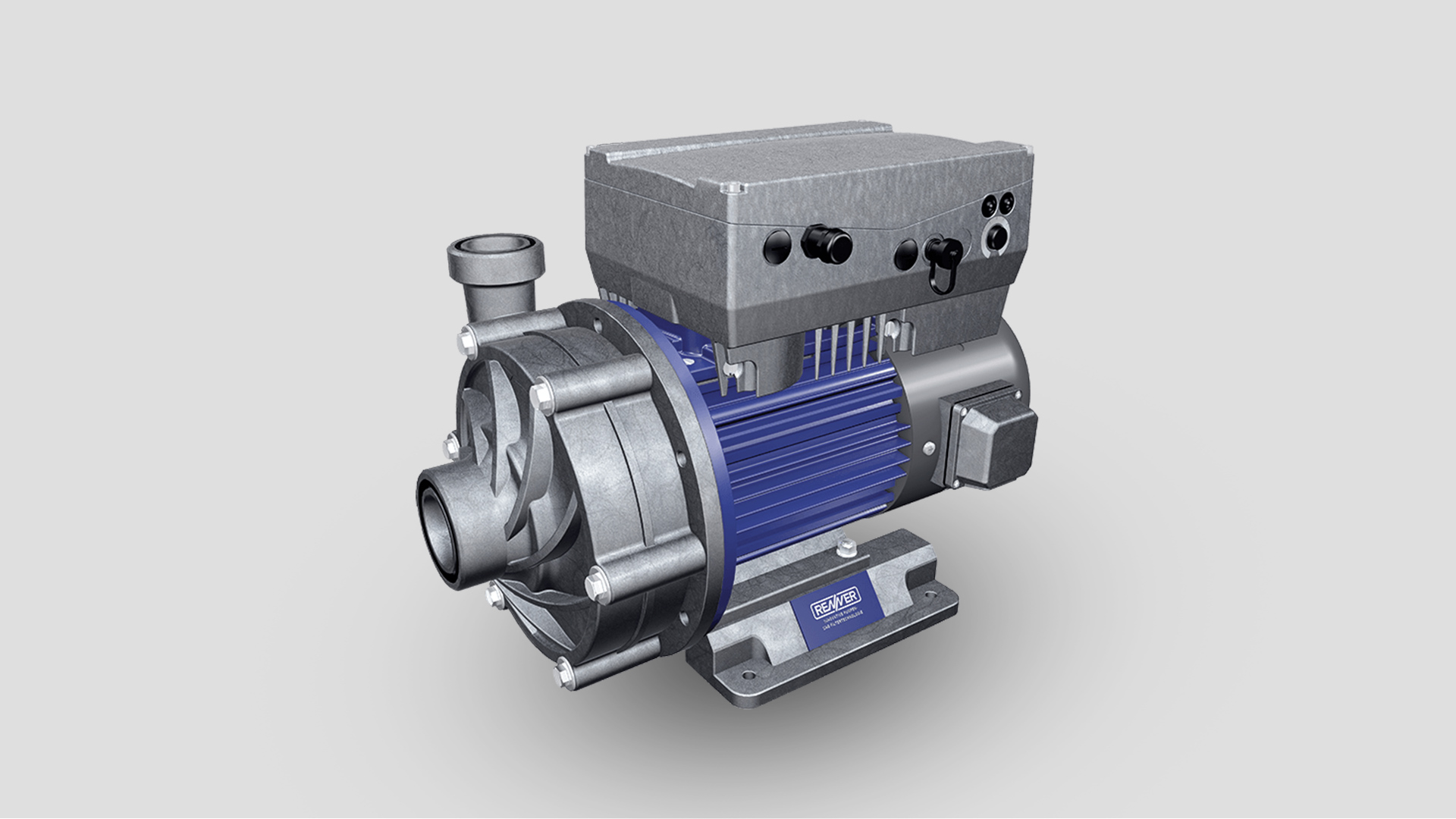

RM-MF Pump series RM with innovative drive [...]

2011

2011

New European Energy Efficiency Directive All pumps [...]

2010

2010

RM-MS – Multi-stage centrifugal pump made of solid [...]

2008

2008

RPR-Control 100 The ideal protection of your [...]

2007

2007

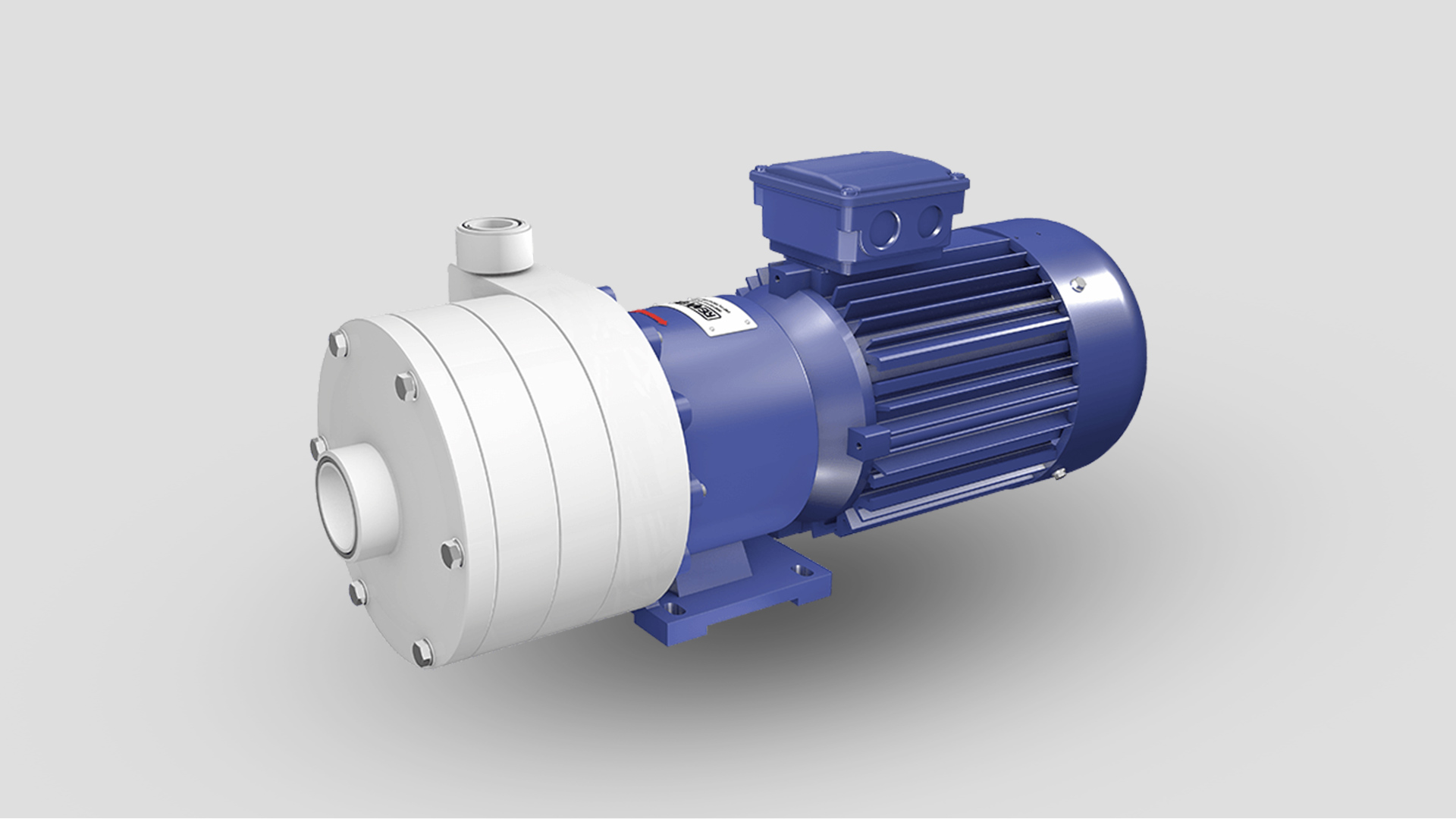

RM-TS – Safe-to-run-dry magnetically coupled centrifugal pumps [...]

2006

2006

25 years anniversary The company owes company [...]

2005

2005

After 24 years of building and continuous development, [...]

1999

1999

The dynamic development in the electronic branch in [...]

1995

1995

Already in 1995 the progress in the CAD [...]